What Is The Working Principle Of PID Controller?

Key Takeaway

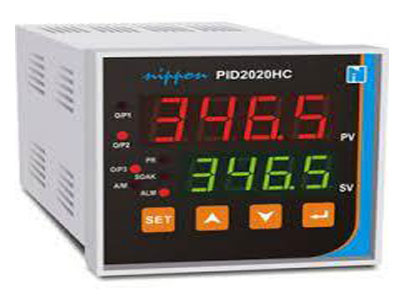

The working principle of a PID controller involves three main components: Proportional, Integral, and Derivative. The PID controller reads a sensor to get the current process variable (PV) and compares it to the desired setpoint (SP). The difference between the PV and SP is called the error.

The controller uses this error to compute three responses: proportional, integral, and derivative. The proportional response depends on the current error, the integral response considers the sum of past errors, and the derivative response predicts future errors based on the current rate of change. These three components are summed to adjust the control variable (CV) and bring the PV closer to the SP. This method ensures precise and stable control of various processes, making PID controllers highly effective in many industrial applications.

Overview of PID Control

PID control is a fundamental concept in automatic control systems. It’s designed to adjust the control variable in a way that minimizes the error between the process variable (PV) and the set point (SP). The PID controller continuously calculates the error value as the difference between the SP and the PV. By applying proportional, integral, and derivative corrections, it ensures that the PV closely follows the SP. This method is highly effective for maintaining stability and accuracy in various industrial processes.

The beauty of PID control lies in its simplicity and effectiveness. Despite being developed over a century ago, PID controllers remain the backbone of many control systems due to their robustness and versatility. They can be used in applications ranging from temperature control in furnaces to speed control in motors. Understanding the fundamentals of PID control will give you a solid foundation in process automation and control.

How PID Controllers Work

A PID controller works by continuously adjusting the control variable based on the error between the PV and the SP. The control action is the sum of three terms: the proportional term, the integral term, and the derivative term. Each of these terms is calculated based on the error value and has a distinct impact on the control action. The proportional term provides immediate correction based on the current error, the integral term corrects past errors, and the derivative term anticipates future errors.

The combination of these three terms allows the PID controller to respond to changes in the process variable quickly and accurately. The proportional term ensures that the control action is proportional to the error, the integral term eliminates steady-state error, and the derivative term reduces overshoot and oscillations. By tuning the proportional, integral, and derivative gains, engineers can achieve optimal control performance for different processes.

Proportional Control

Proportional control is the first component of a PID controller. It produces an output that is proportional to the current error value. The proportional gain (Kp) determines the magnitude of the correction applied to the control variable. A higher Kp results in a larger correction for a given error, leading to a faster response. However, if Kp is too high, it can cause the system to become unstable and oscillate around the set point.

Proportional control alone is often insufficient to achieve the desired performance, as it cannot eliminate the steady-state error completely. This is because the control action is directly proportional to the error, meaning there will always be some residual error unless additional control actions are taken. Nevertheless, proportional control provides the foundation for more sophisticated control strategies by quickly addressing the current error.

Integral Control

Integral control addresses the limitations of proportional control by focusing on past errors. The integral term accumulates the error over time and applies a correction based on the cumulative error. The integral gain (Ki) determines the strength of this correction. By integrating the error, this term eliminates the steady-state error, ensuring that the process variable reaches and stays at the set point.

The integral action is particularly useful for processes where even a small steady-state error is unacceptable. However, it must be tuned carefully, as excessive integral action can lead to a phenomenon known as “integral windup,” where the controller overshoots the set point and oscillates. Engineers often implement anti-windup strategies to prevent this issue and maintain stable control.

Derivative Control

Derivative control predicts future errors based on the rate of change of the error. The derivative term applies a correction that is proportional to the rate at which the error is changing. The derivative gain (Kd) determines the strength of this correction. By anticipating future errors, derivative control helps to reduce overshoot and dampen oscillations, leading to a smoother response.

Derivative control is especially beneficial in systems where rapid changes in the process variable can cause instability. However, it is sensitive to noise in the error signal, as it amplifies high-frequency components. To mitigate this, engineers often use filtering techniques to smooth out the error signal before applying derivative control. Despite its sensitivity, derivative control enhances the performance of the PID controller by providing a predictive element to the control strategy.

Conclusion

Mastering the principles of PID control is crucial for any engineer involved in process automation and control. PID controllers are versatile and powerful tools that can maintain stable and accurate control in a wide range of industrial applications. By understanding how proportional, integral, and derivative control actions work and interact, you can design and tune control systems to achieve optimal performance.

In summary, the proportional term addresses the current error, the integral term corrects accumulated past errors, and the derivative term anticipates future errors. Together, these components form a comprehensive control strategy that can handle various process dynamics. As you gain experience, you’ll develop a deeper understanding of how to tune these controllers to meet the specific needs of different processes. This knowledge will empower you to create efficient, reliable, and responsive control systems, contributing to the overall success of your industrial operations.