What is the ISO standard for light curtains?

Key Takeaway

The primary ISO standard for safety light curtains is ISO 13855, which outlines the positioning of safeguards relative to the approach speeds of parts of the human body. It is crucial for ensuring that light curtains are installed at correct distances to effectively prevent access to hazardous areas before a person can reach the danger zone. This standard helps manufacturers and users of light curtains design systems that provide robust safety measures, thereby reducing the risk of accidents in industrial settings. For detailed application and compliance guidelines, referring directly to ISO 13855 is recommended.

The Basics of ISO Standards for Safety Devices

ISO standards serve as an international framework for ensuring the safety and reliability of various devices, including light curtains used in industrial settings. These standards dictate rigorous testing protocols, design requirements, and performance criteria that must be met for safety devices to be certified. By standardizing the requirements, ISO helps maintain uniformity in safety across different markets and manufacturers, which is crucial for protecting workers and ensuring smooth operation across global supply chains. For light curtains, these standards ensure that no matter the manufacturer, the devices are capable of performing to a set minimum standard of detection and interruption of hazardous operations.

Analyzing the Core Requirements of ISO Standards for Light Curtains

The core requirements of ISO standards for light curtains focus on ensuring the effectiveness and reliability of these safety devices in preventing injuries and fatalities in industrial environments. These standards typically cover aspects such as minimum response times, sensitivity levels, the resilience of the system under various environmental conditions, and the ability to detect breaches of varying sizes and at different speeds. Compliance with these standards means that light curtains must consistently perform under specified conditions, thus ensuring they are capable of halting potentially dangerous machinery the moment a risk is detected.

Technical Specifications of ISO Standards for Light Curtains

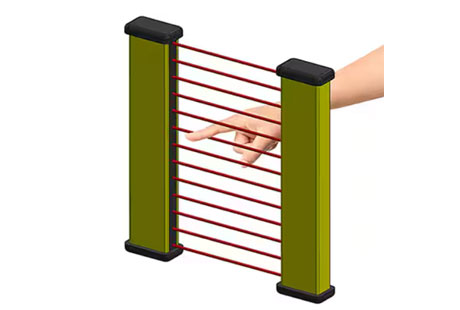

The technical specifications detailed in ISO standards for light curtains include criteria such as the size of the area covered, the type of light beams used (infrared, for example), and the spacing between these beams. These specifications also dictate how light curtains integrate with other safety and control systems, requiring that they have fail-safe mechanisms and compatibility with emergency stops and other protective measures. Adherence to these technical standards ensures that light curtains can effectively prevent access to hazardous zones and provide a reliable safety barrier in automated and manual industrial operations.

Steps to Ensure Your Light Curtains Meet ISO Standards

Ensuring that light curtains meet ISO standards involves several crucial steps, starting from the selection of certified products to regular maintenance checks. Initially, it’s imperative to select light curtains that are explicitly marked with ISO compliance, indicating they have passed stringent safety tests. Installation should be carried out according to the manufacturer’s guidelines, which should align with ISO requirements, ensuring proper alignment, height, and distance from the hazard zones as specified.Post-installation, conducting initial testing and calibration in the presence of a certified safety engineer ensures the system’s responsiveness and coverage meet the necessary standards. Regular maintenance and testing should be scheduled, not just to comply with ISO standards but to adapt to any changes in the working environment that could affect the device’s effectiveness. Documentation of all tests and maintenance procedures should be meticulously kept as part of compliance with ISO standards.

Conclusion

Adhering to ISO standards for light curtains isn’t just about regulatory compliance—it’s about ensuring the highest level of safety in industrial settings. These standards provide a framework that helps manufacturers design, test, and implement safety devices that reliably protect workers from potential harm. By rigorously following these standards, companies not only safeguard their employees effectively but also enhance their operational integrity and maintain industry credibility.

Adoption of ISO standards in safety practices, including the use of light curtains, leads to an environment where safety is predictable and verifiable, minimizing risks and fostering a culture of safety and responsibility. This proactive approach in adhering to established standards significantly reduces workplace accidents and builds a foundation for continual safety improvements in ever-evolving industrial landscapes.